|

|

|

|

Column Lock Bolt Replacements

Fig. 1 November, 2011. When I removed the bolts that clamp the head to the column (this is a high torque area), I saw that the threads were pretty distorted. In the picture above, I am comparing one with a grade 8 bolt of the same thread (but the wrong length, wouldn't you know it?) I tried to get a better picture, but the threads look much worse than the picture shows. They will not allow the nut to go on without a wrench on it. This is due to the fact that they were just plain ole soft steel bolts and the torque involved stretched the threads. I will replace them with Grade 8 bolts and nuts, and I will also replace the regular washer with a bronze Oillite bearing washer that makes tightening and loosening much easier. BTW, I read an analysis somewhere that talked about the clamping force of a bolt, and that of the torque applied, only about 30% of the force goes to clamping pressure - the rest is used up in overcoming friction on the threads and friction of the nut against the washer. A bearing washer helps mitigate this, allowing more of the applied torque to be converted to clamping force rather than being wasted on friction. The hardened nuts I had, and I've noticed they are available from big box hardware stores, but they don't have grade 8 bolts that long or the oil bronze washers, so I ordered 7" 1/2-13 dia bolts from McMaster-Carr.

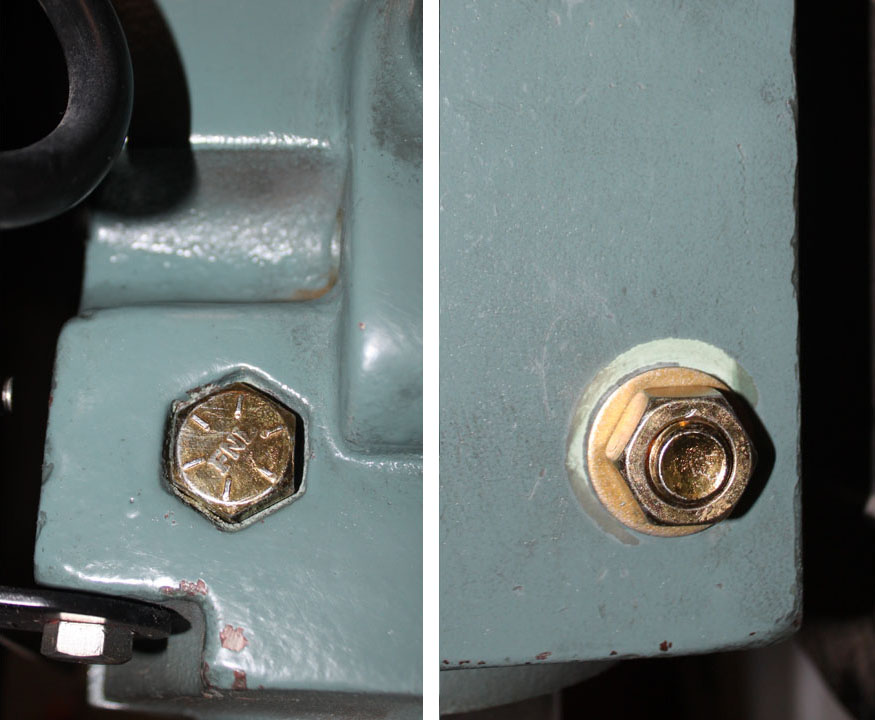

Fig. 2 Problem! The grade 8 bolts from McMaster won't work because the head is too small to grip the cast hex insert on the side of the mill. I mistakenly assumed that the bolt used on the mill was made according to some standard, paying attention solely to the threads and not the head size. After measuring, the bolt on the mill is a non-standard 1/2-13 inch bolt with a 9/16 inch bolt head. You can see the head difference in the above photo. I went to a local Fastenal store and although they didn't have a 1/2 inch bolt that would work, they did have a 9/16 bolt with the right sized heads that may work, so I got a couple of 9/16 nuts to match.

Fig. 3 The 9/16 bolts fit fine - their heads matched the old bolts and the case holes were already oversize, and the column diameter was not a problem, although mills with other sized columns might be. The new hardened bolt, nuts, and washers now allow a quite noticeably smooth and firm clamping. Note: I later found this problem to be well documented on Alan Pinkus's website, which would have saved me some trouble if I had only seen it earlier. He had to turn down part of his bolts because his column diameter was larger. |

|