|

|

|||||

|

December, 2011. There isn't any good lighting where my mill is right now, so it really needs some task lighting. The ones you have to position always seem to have shadow issues. On the web I've seen some guys make some lighting out of "LED auto rings" sold on Ebay. (I don't know who originated the idea, but thanks, whoever you are!) These auto rings are just round pc boards with a bunch of LEDs and resistors soldered onto them to make them 12v compatible. (Search Ebay for "Headlight LED ring".)

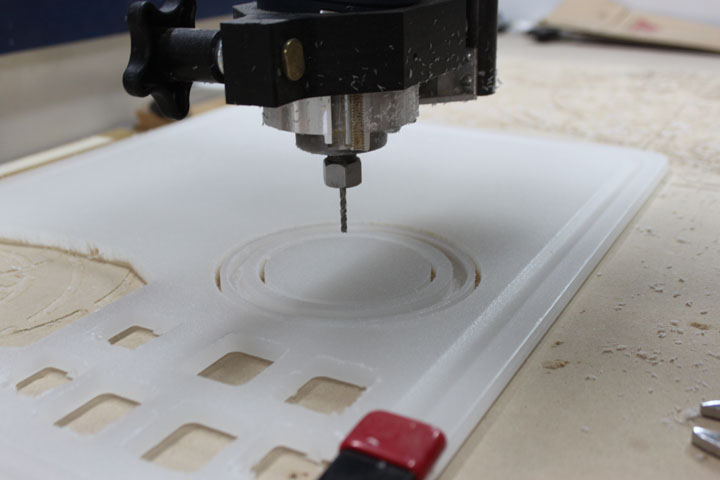

Fig. 1 I measured the diameter of the quill bottom, which was 90 mm or 3.542 inches. With that dimension in mind I ordered a 120 mm auto ring for $6 that had 39 LEDs on it. When the ring arrived, it measured 9 mm wide. I then designed an attachment ring with a pocket that will house the LED ring, and converted it into a toolpath for my CNC. Figure 1 above shows the ring just after being cut on my CNC from a slab of polycarbonate (it's Walmart kitchen cutting board - sometimes just the right material that machines well and is cheap!) I had on hand. I then drilled a slot on the top of it for the wires to exit.

Fig. 2 Above shows a picture of one of the rings as it comes in a bag, (I am making another one for a friend) and the other one is placed into the mounting ring. It is a nice press fit, but I will probably glue it in later (I find E6000 glue sold in hobby stores works well on this cutting board material.) I already had a 12v DC wall wart in my junk box, so I am in business. I hooked it up and measured its current draw at 200 ma.

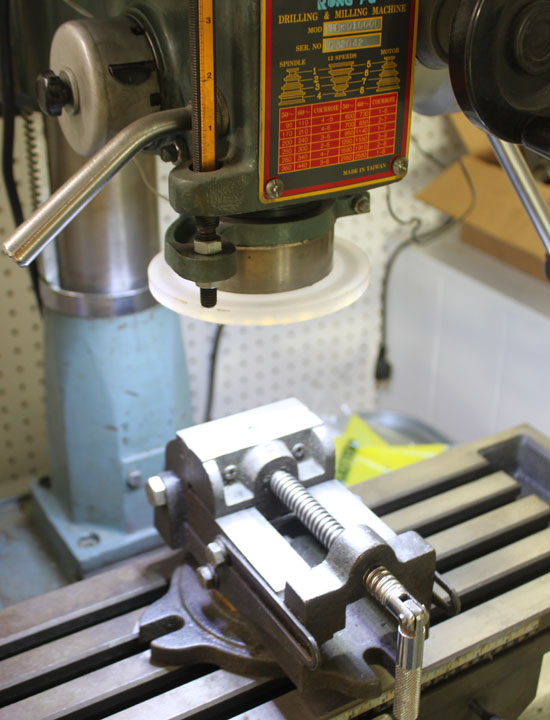

Fig. 3 Above shows the light installed on the mill by just a press fitting. I don't know the light wavelength or the black body temperature of these LEDs, but they seem to emit a cool white light - but not like some of the bluish ones I've seen. Also, I don't know how many lumens are showing here, but it seems to be plenty bright enough for spotting center marks, scribe lines, and just watching the chips fly. At first I thought there might be a shadow from the tool itself right under its tip, but there is plenty of light where a drill bit is about to touch. This ring has the advantages of an evenly distributed light, practically no heat to worry about, no bulbs to shatter from flying shrapnel (I mean chips, of course), it only cost me $6, and being driven at this low a current, it should have a very long life. This idea would also work just as well for drill presses.

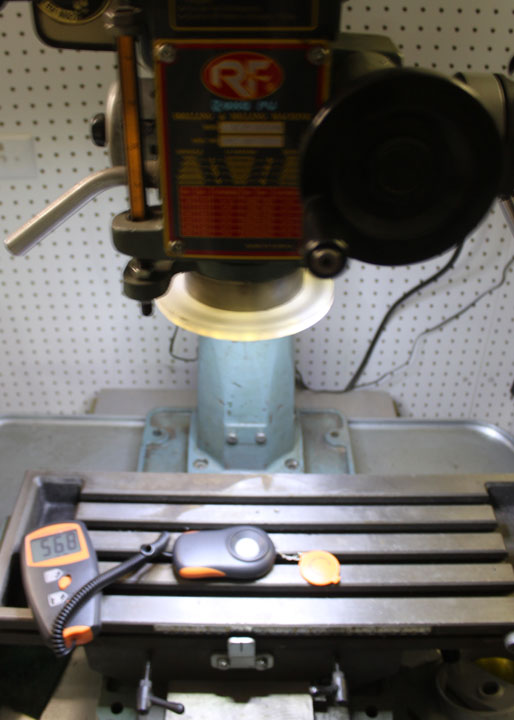

BTW, I decided to measure its output just see how things sized up. In photo 4a above, I measured the output of the LED ring 12 inches away from the light at 546 lux with no other ambient light. In photo 4b, just for comparison I measured several light bulbs - no ambient light, same fixture, same light meter at the same distance. I also turned the face of the sensor directly toward the bulb, but it made no difference, so I left it flat each time. A 40 watt incandescent bulb produced 420 lux. A 60 watt incandescent bulb gave off 912 lux, and a 100 watt one gave off 1740. These were all household type white bulbs and I waited a few minutes for each one to get up to temperature. Just for fun, I also tried some of those CFL bulbs - a 13 watt one (supposedly 60 watt equivalent) turned on at 340 lux but within 4 minutes settled down at 936 lux. A 26 watt CFL (supposed 100 watt equivalent) turned on at 154 lux, but also got up to 1290 after about 4 minutes. So, based on this simple experiment, it looks like the 39 LED ring light on the mill is roughly the same as a 50 watt bulb. I normally use a 60 watt bulb for this kind of task lighting as a 100 watt bulb is just too hot to work around. I suppose if you made a ring light with a 120mm ring and a 180mm ring around that, you would be close to a 100 watt equivalent. However, the light ring I made seems like plenty of light even for my eyes, mostly because it is always just a few inches from the work, like in Figure 3. |

|||||